Micro Precision Parts Machining

Miniature Parts Machining

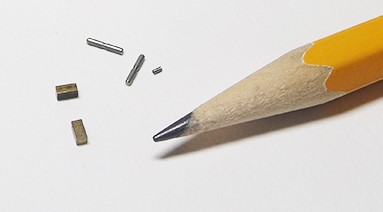

When micro precision is paramount, we turn to the Tornos Swiss Nanos for miniature parts machining. These machines are designed to meet demands for extremely small, high-precision workpieces. With 8 axes of motion, 2 independent tool systems, and a flexible machining area, it’s the ideal choice for a broad range of micro workpieces requiring quality, precision, and efficiency. Available to produce high volume screw machined products, Cox machines up to 1.7 million precision components every week.

Request A Quote

CNC Micromachining pushes the limits of precision and size. Using extremely precise tools, tight tolerances, and machines that specialize in this area, allows the manufacturing of intricate micro components used most notably in the medical and electronics industry. Most features of miniature machined parts are not visible to the naked eye without magnification, thus requiring the use of very high-resolution inspection equipment for micromachining services.

For even more complex work micromaching services, requiring up to 12 axes of motion, we utilize our fleet of 45 Tornos Deco CNCs.

Miniature Machined Parts

- Micro Gears

- Micro Shafts

- Micro Fittings

Our micromachining expertise is critical in various industries, including

Request A QuoteCertifications and Quality

- ISO 9001:2015 certified

- ITAR Registered

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA for automotive customers

- Industry 4.0 advanced quality system

- Fully compliant with the exacting requirements of our customers

- Skilled in KanBan and other customer driven quality and inventory management systems

- Proprietary 100% automated inspection available