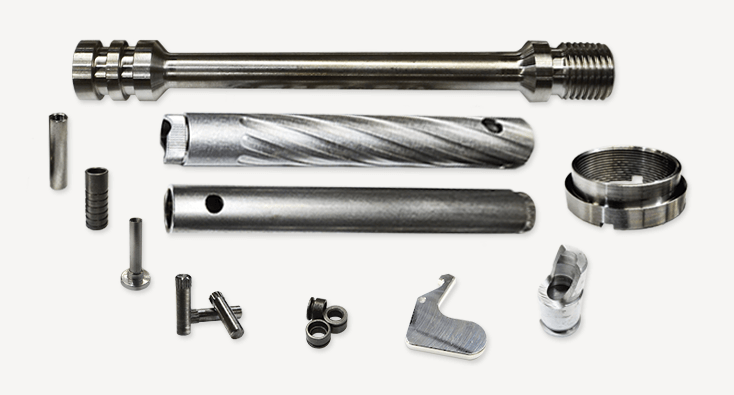

Firearm Machined Parts Manufacturer

Precision CNC Machined Firearm Components

Firearm machined parts manufacturers recognize that Cox Manufacturing always hits the mark when producing large quantities of parts that are reliable, on-time, and cost efficient. Our high volume firearm machining expertise includes high volume firearm machined components that are confidently delivered to the precise specifications the industry requires. Available to produce high volume screw machined products, Cox machines up to 1.7 million precision components every week.

Request A Quote

To read more about Cox Mfg's involvement in manufacturing these rimfire firing pin indent copper crushers, click here.

High Volume Firearm Machining Advantages

Cox Manufacturing remains a hit with professionals in the firearms industry due to our full arsenal of CNC Firearm machining capabilities:

- Deep experience complying with documentation and certification requirements, such as DFARS material source standards and compliance with ITAR controls

- The exceptional precision of CNC Swiss machining, multi-spindle cam automatics, and CNC turning centers

- An Esprit CAD/CAM system to precisely produce the most elaborate geometries (complete equipment list)

- The ability to machine materials other manufacturers won't, including copper, plastics and exotic alloys that meet the special requirements of advanced weapons systems

Firearm Parts Machining Applications

- Firing Pins

- Muzzle Brakes

- Flash suppressors

- Detents

- Detent Plungers

- Screw Sets

- Locking Screws

- Extractor Plungers

- Trigger Pins

- Pivot Pins

- Spacer Washers

- Bushings

In an industry where parts are made only of the highest caliber, Cox takes pride in remaining in the sights of pacesetters in the firearm industry as a high volume firearm parts manufacturer.

Firearm Parts Machining Case Study

A leading OEm had Cox Manufacturing a part requiring two additional operations. Our team suggested a change in material to pre-hardened steel for a vanity part which led to eliminating a critical failure mode. Whith this shift, we removed the two additional steps in the manufacturing process--heat treatment and rethreading--resulting in significant cost savings and substantial lead time reductions. To support the transition, we ran a trial no extra expense to the customer. This proactive collaboration not only saved weeks of lead time, but also streamlined the process, enhancing both reliability and cost efficiency.